The diaphragm and valve core are pressed against the valve seat by the internal spring. When the pressure in the pipeline system exceeds the preset pressure, the diaphragm and the min core are pushed up, and the medium is discharged to the return pipe and container, which can be adjusted on site. The screw uses the pressure gauge in the pipeline to set the pressure in the range of 0~1.0Mpa. The relief pressure is generally set to be higher than the system pressure 0.1-0.2Mpa. The pressure adjustment of the safely valve is not allowed to exceed the maximum pressure of the pump, The installation is generally as close as possible to the pump, At the outlet, there should be no valve between the pump and the safety valve to protect the safety of the pump and the normal operation of the system.

Release the pipeline pressure to ensure the stability of the system pressure;

Protect the safety of the pump and the normal operation of the system;

Used in conjunction with a pulse damper to reduce the harm of water hammer to the system and achieve superior low-vibration adjustment effects;

Reduce the peak value of flow rate fluctuations and protect the pipeline system from pressure fluctuations;

The diaphragm adopts advanced PTFE+rubber compound technology, which is suitable for almost all corrosive fluids, and the sealing is reliable and leak-free.

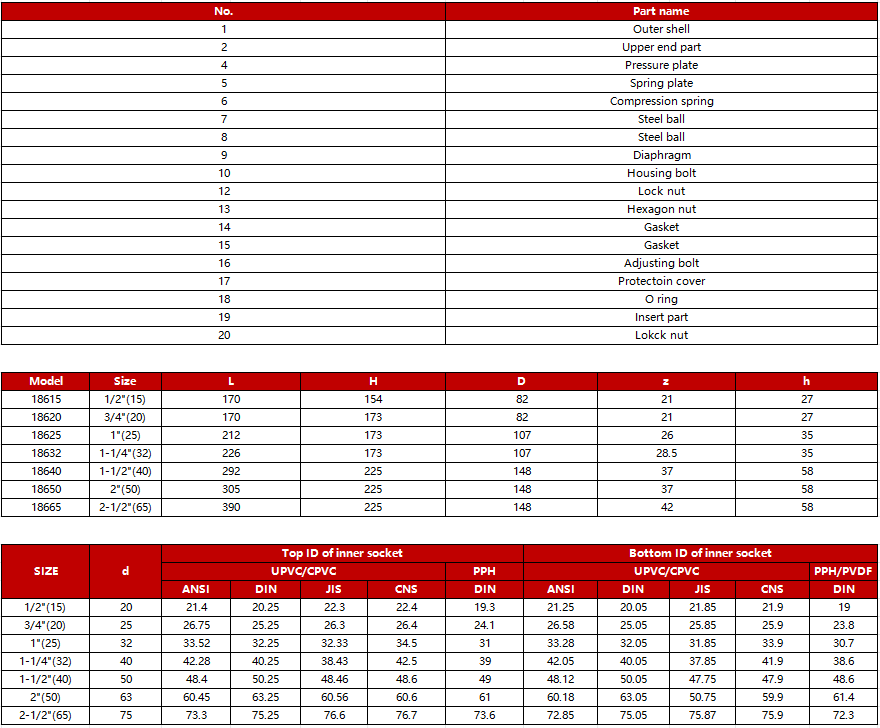

Technical Parameter

Material: UPVC/PPH/CPVC/PVDF

Working pressure: 0~1.0 Mpa, 0.2~1.6 Mpa

Size: DN15~DN65

Connect method: Socket end, flange end, thread end

Diaphragm material: PFTE+EPDM compsite